Since 1984

LI-BE has been synonymous with special bearings

Born in the linear handling sector, where it introduced patented solutions, LI-BE later expanded its expertise to the steel industry and machine tools. Today, thanks to a fully integrated production chain and consolidated know-how, we tackle every critical motion application with roller or ball bearings.

Our path has always been focused on developing expertise: from design to advanced simulation, up to the production of unique components capable of combining precision, durability, and high performance. Every project is an opportunity to refine our technical knowledge and turn it into reliable solutions, built around the customer’s needs.

With an approach that combines experience and constant technological progress, we position ourselves as a partner for those looking for more than just a bearing supplier: a technical counterpart capable of analyzing complex problems and turning them into concrete results.

Digital Twin

LI-BE’s strengths lie in the technical expertise and engineering of its design and production processes, which culminate in the SEL series of super-precision bearings for machine tools and customised products for the STEEL industry.

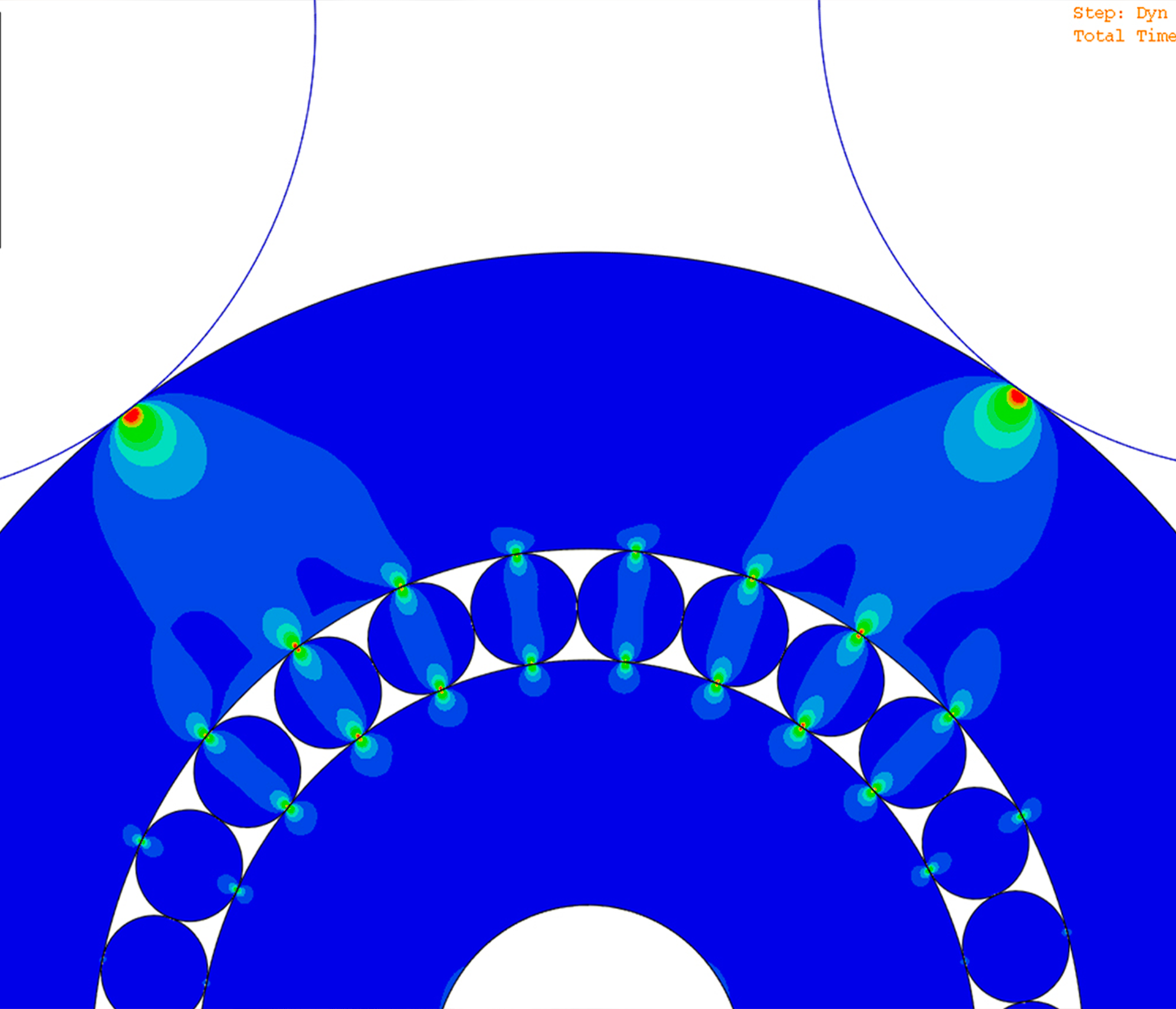

The use of digital twin forms the basis of LI-BE’s technical development. FEA and specific internal software applied to the digital twin allow us to have a clear view of the consequences of the load on the bearing, knowledge that, until a few years ago, was held by only the most renowned manufacturers.

Know-how, the high quality of its products and the typical desire of those who want to stand out in an increasingly demanding industrial landscape make LI-BE the ideal partner for high-tech solutions.

In-house production departments

With an experienced technical team and our own production facility in northern Italy, we are able to offer cost-effective, turn-key solutions to specific customer needs.

VISIT US

LI-BE places development, product quality, and customer transparency as its fundamental pillars. Our facility reflects our pride in a genuinely Made in Italy production, a heritage we are eager to openly share with you.

Step into the world of LI-BE, where innovation and tradition merge in the creation of precision products.

Click Visit Us to explore an interactive experience

Turning

Lathes with motorized tools and CNC machining centers are programmed thanks to a CAM that dialogues directly with the project files thanks to a dedicated PDM. Renishaw in-process control systems monitor the tool wear to ensure high quality, repeatable geometries.

Grinding

22 grinding machines that can work inside diameters, outside diameters, and faces, ensure high precision in the final machining stages. The machinable diameters range from 20 mm to 1250 mm. Marposs in-process and post-process control systems ensure high quality, repeatable geometries.

Assembly

The department where our specialized personnel, with strong expertise, assemble and lubricate our products, preparing them for shipment.

SEL quality

Quality department dedicated to our super-precision bearings such as the SEL line for machine tools. Dedicated tools, sub-micron CMM mesuring machine, controlled atmosphere and the expertise of our specialist personnel guarantee high quality standards.

Quality

Equipped with controlled atmosphere and dedicated measuring instruments to check both the finished standards components and the machining steps.